Product Information

What is Vacuum IQ™?

Vacuum IQ™ is an electronic motor control and software program designed for motor-driven centrifugal vacuum and pump systems that automatically adjusts motor speed to changing load requirements.

The result is equipment that “thinks” for itself and matches production to demand at any given time. The most significant benefit Vacuum IQ™ offers is dramatic energy savings. Vacuum IQ™ also extends equipment life, reduces maintenance and downtime costs, and often increases productivity. Vacuum IQ™ combines the technology of a variable frequency drive (VFD) with AutoVac’s proprietary computer programming that is customized for each industrial application. Its Windows based operating platform can be interfaced with existing equipment and allows for comprehensive motor control and easy data retrieval.

Continuous Tracking

Vacuum IQ™ constantly monitors your vacuums so they always operate at maximum efficiency. Your motors work as much or as little as needed depending on the actual demand for suction. You enjoy the most cost-effective operating model– vacuum-on-demand. Vacuum IQ™ dramatically reduces energy costs and extends the life of your equipment.

Real Cost Savings

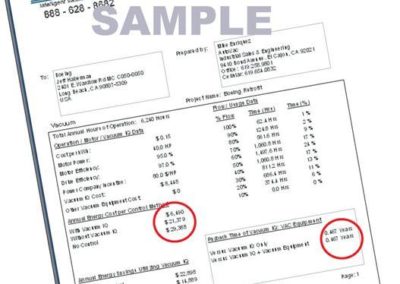

Need more incentive? Energy providers across the country are issuing substantial rebates for installing environmentally friendly devices like Vacuum IQ™.

AutoVac will provide you with a cost savings analysis that shows how much money you’ll save on your energy bill. Your energy provider will use this report to calculate your rebate for installing Vacuum IQ™ (where available).

- Dramatically cut energy costs by reducing energy consumption

- Extend the life of your equipment

- Reduce maintenance costs and equipment downtime

- Simplify your equipment – Vacuum IQ™ replaces soft starters and throttle valves

- Return on investment is months, not years

- Savings continue year after year

- Earn a rebate from your energy provider for “Going Green” with Vacuum IQ™ (participation varies by region)

- Vacuum IQ™ brought one client’s annual energy costs down from $29,388 to just $6,490 – that’s a savings of 77.9%.

- Return on investment is realized in less than six months!

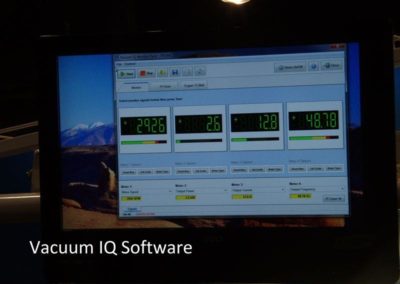

User-Friendly Software

Vacuum IQ™ includes user-friendly software that interfaces easily with virtually any vacuum equipment. The program allows comprehensive motor control and easy data retrieval.

- AutoVac can monitor your system online via the web for troubleshooting and diagnostic purposes

- Enjoy online control of your motors to perform auto-tunes, test parameter adjustments and simulate events

- Download and save data to a drive or file

- Track your exact savings with the built-in cost savings calculator

Product Specifications

How It Works

Once Vacuum IQ™ is installed and programmed for a specific application; the operating speed of the connected motor is varied by changing the frequency of the motor supply voltage. This allows continuous airflow speed control within the parameters of your specific application. Motor-driven systems are often designed to handle peak loads that have a safety factor. This often leads to energy in efficiency in systems that operate for extended period sat reduced load. The ability to adjust motor speed enables closer matching of motor output to load and results in tremendous energy savings.

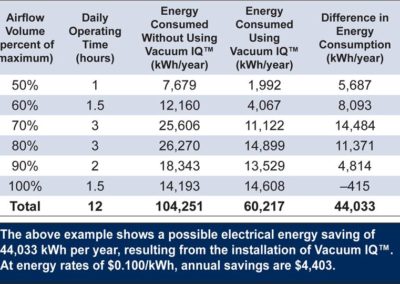

Many motor-driven centrifugal vacuum and pump systems operate for extended periods at reduced load with airflow restricted or throttled. In these centrifugal machines, energy consumption is proportional to the cube of the flow rate. Even small reductions in speed and flow can result insignificant energy savings. Vacuum IQ™can offer significant energy and cost savings by reducing the operating speed when the airflow requirements are lower. Vacuum IQ™ can also increase productivity, improve product quality and process control, and reduce maintenance and downtime.

The Science Behind It

Induction motors, the workhorses of industry, rotate at a fixed speed that is determined by the frequency of the supply voltage. Alternating current applied to the stator windings produces a magnetic field that rotates at synchronous speed. This speed may be calculated by dividing line frequency by the number of magnetic pole pairs in the motor winding. A two-pole motor, for example, has one pole pair, and therefore the magnetic field will rotate 60Hz / 1 = 60 revolutions per second, or 3600 rpm. The rotor of an induction motor will attempt to follow this rotating magnetic field, and, under load, the rotor speed “slips” slightly behind the rotating field. This small slip in speed generates an induced current, and the resulting magnetic field in the rotor produces torque.

Since an induction motor rotates near synchronous speed, the most effective and energy-efficient way to change the motor speed is to change the frequency of the applied voltage. Vacuum IQ™ converts the fixed frequency supply voltage to a continuously variable frequency, thereby allowing adjustable motor speed. Vacuum IQ™’s proprietary software allows you to determine the parameters to meet your application.

Power Laws

Q ∞ Speed P ∞ Speed2 KW ∞ Speed3

Q = Flow P = Pressure KW = Power

Flow in a system is determined by the speed of its pump or fan (in this case a centrifugal vacuum producer).The pressure delivered varies as the square of the speed. So, as you double the speed you deliver four times the pressure. The power required consequently, varies as the cube of the speed – which means if you double the speed you need eight times as much power. On the flip side, if you halve the speed you halve the flow but you only need one-eighth of the power.

1/2 speed = 1/2 flow = 1/8 power

Energy savings made possible by reducing airflow are exponential – so are the cost savings in real dollars. AutoVac offers a complete line of motor controls and intelligent vacuum systems.

Options

- Custom software for any application

- Enclosure cooling systems

- Ethernet card for remote monitoring TCP/IP

- Logic controller and PLC interface kit

- NEMA 12 4X or 3R enclosures

- Remote digital operator kit

Product Features

- User-friendly software interface

- Digital keypad for easy manual input

- RJ-45 style digital connector

- 24V DC control logic for sourcing or synching outputs

- UL CUL and CE listed

- MTBF exceeds 28 years

- Compatible with most vacuum systems

- Input/output bypass connectors

- 24 hour service and support

Software Features

- View and modify drive data with a simple user interface

- Download and save data to a drive or file

- Ability to save parameter or graph data as comma separated variable (.csv) file for use with other software applications such as Microsoft EXCEL

- Online monitoring for troubleshooting and diagnostic purposes

- Fault history of drive

- Digital scope feature for graphing drive data

- Basic online control of the drive to test parameter adjustments, simulate events, and to perform motor auto-tunes

- Cost savings calculator tracks exact savings